MultiCOM

MultiCOM software module in Windows environment allows the simultaneous link to the peripheral devices connected to the PC and can be activated directly from the CNC keyboard without any input from the management PC.

Functions

- Simultaneous communication :

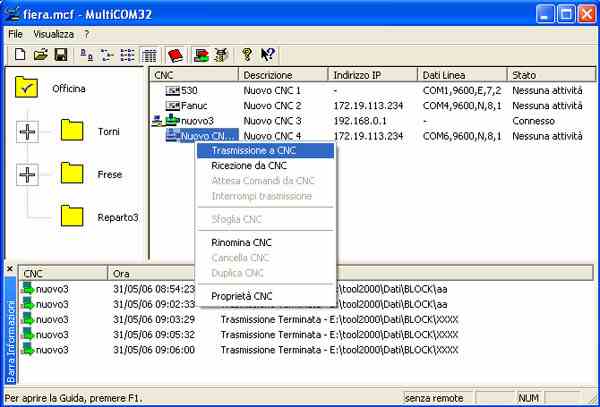

simultaneous transmission and/or reception of ascii or binary files to as maximum of 128 RS 232 C peripheral devices via multiport serial board, ethernet or wireless. - Part program Remote management:

file transmission and/or reception through commands sent from the NC. The commands are inside files on the CNC. - RCM remote management:

file transmission and/or reception through commands sent from light pens, barcode readers, computer terminals or PC in LAN. - Line state display:

possibility to install a display near the CNC keyboard which highlights the line state and the availability of the management PC ( V.S.M. ). - Communication monitoring:

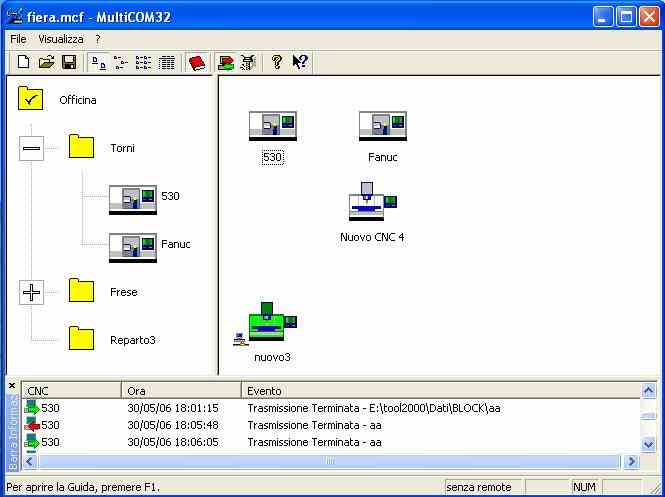

information displayed on the screen highlighting the state of the communication line by means of a synoptic table of the workshop layout. - Event log :

display and record of activities carried out between the management PC and the CNC peripherals. - Syntactic check:

of the program to be sent or received on the PC and comparison between Part-Programs. - Integrated management of CNCs in LAN:

management by browser specialized in transmission from / to CNC in LAN. - Integrated management of CNC states:

state acquisition, display and storage on DB (CNC ON, axis movement, spindle, Override Feed, T.C.) acquired by means of specific hardware. (Ref. MDA software) - Additional information:

Storage of program information (order, Customer, drawing, notes...) with possible assisted research. - Part program local management:

file transmission and/or reception through commands given from MultiCOM interface panels, while keeping the communication in progress. - Hardware and software requirements:

USB port

RS232 C serial port

Windows XP or later

MultiCom - Windows service

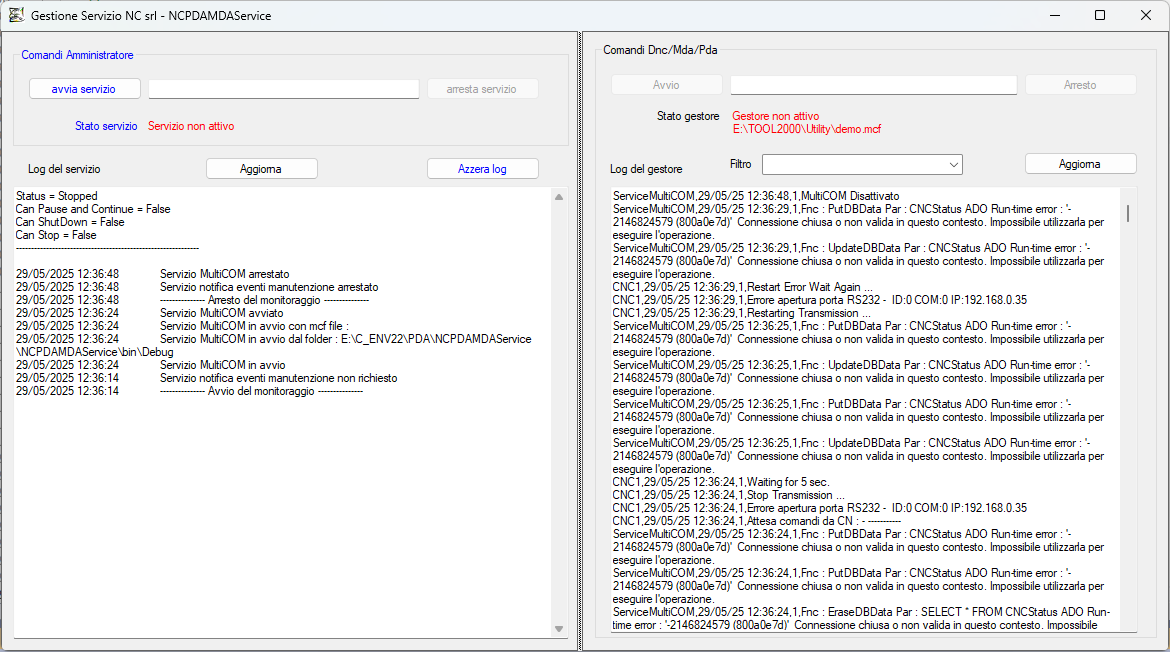

For advanced management of the transmission control system, the version of MultiCOM available as a Windows service can be activated. This version is aimed at companies that wish to manage the system on machines that are not accessible to all users and that are always available without human intervention. The functionality of the application remains unchanged; it will therefore be possible to manage both the management of program transfer to CNCs (DNC service), the acquisition of machine states for Industry 4.0 (MDA service) and the management of production progress (PDA service). In this mode, the service can be managed by a manager via a specific console. It will therefore be possible to start/stop the service, interrupt/resume DNC/MDA/PDA management and monitor the service logs in the event of specific maintenance. The service has the advantage that it is started automatically by the system at each reboot, without operator intervention following periodic machine updates, for example.

Daily monitoring of transmission status and status acquisition is available through a synoptic panel displayed as a WEB page accessible from any client PC. The same interface also allows the usual operation of the MultiCOM system, such as stopping and restarting a communication, manual transmissions, etc. For further information please refer to the Industry 4.0 page